JWP graphene anti-wear agent, developed by China and the United States, and adopts a new type of carbon nanomaterial graphene, which is currently the thinnest, strongest, strongest self-lubricating and conductive material found.

The Graphene Quantum Dots in the JWP graphene antiwear agent have higher chemical stability than other quantum dot materials, and can withstand extreme environments with strong acids, strong bases and higher temperatures. Suitable for automobiles, ships and other industrial parts.

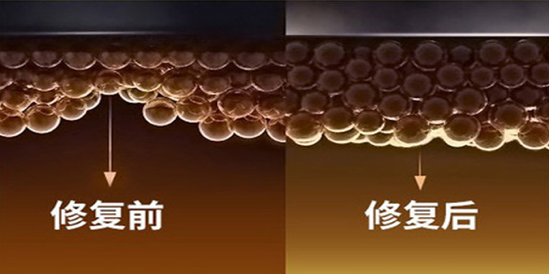

JWP graphene anti-wear agent is different from general anti-wear agents in the market. It can lubricate moving parts for a long time. At the same time, it can form a layer of wear-resistant, tough and lubricating graphene protective film on the metal surface to reduce mechanical damage.

Compared with other traditional lubricants, graphene additives provide pure physical protection without unstable effects such as chemical decomposition and provide long-term protection. JWP graphene anti-wear agent and engine oil are fully mixed to fully play the role of lubrication, cooling, rust prevention, cleaning, sealing and buffering, and restore the smoothness of the engine for your love horse.

Material Safety Data Sheet(MSDS) is a comprehensive regulatory document on the characteristics of chemicals provided by chemical production, trade, and sales companies to downstream customers and the public in accordance with legal requirements. It provides 16 items including physical and chemical parameters, explosive properties, health hazards, safe use and storage, leakage treatment, first aid measures, and related laws and regulations.

Before use, please shake it vigorously and evenly for better results.

- Please put it into the oil tank marked as

It is strictly forbidden to put it into the gasoline/diesel tank, otherwise you will be responsible for the consequences.

It is strictly forbidden to put it into the gasoline/diesel tank, otherwise you will be responsible for the consequences. - The recommended dosage for cars, MPVs, and SUVs is 200ml.

- The recommended dosage for large industrial vehicles is 400ml.

- Please contact the manufacturer before using the ship or aircraft to determine the injection amount according to the amount of engine lubricating oil.